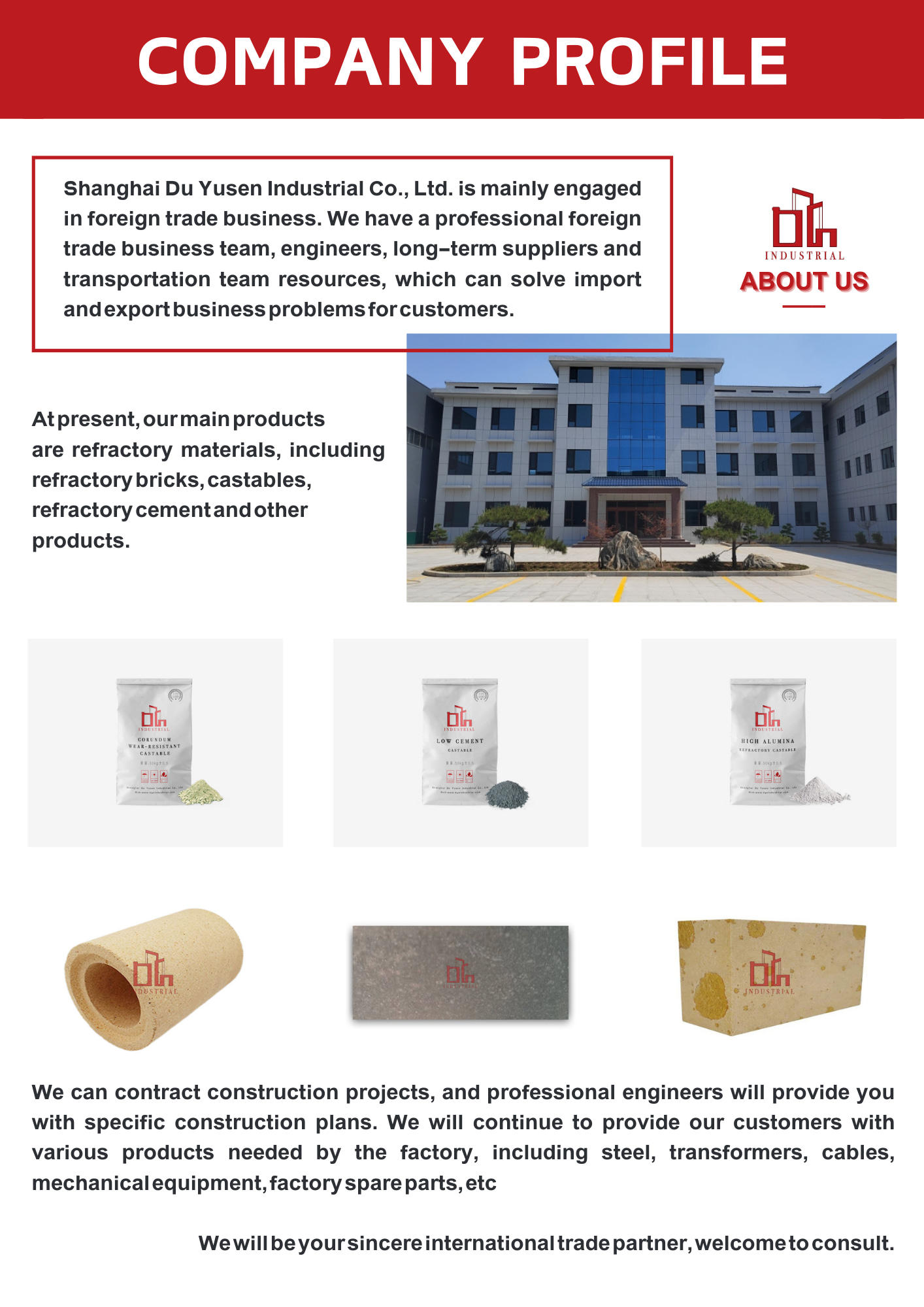

Silicon bricks, also known as silica bricks or silicon carbide bricks, are a type of refractory material commonly used in glass kilns and other high-temperature applications. They are made primarily from silica (SiO2), which is a key component of sand and quartz.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

| Item | Unit | DYSSBG-96a | DYSSBG-96b | DYSSBG-95 | |

| SiO2 | ≥ | % | 96 | 96 | 95 |

| FeO3 | ≤ | % | 0.6 | 0.8 | 1 |

| Melting index, Al2O3+2R2O3 | ≤ | % | 0.5 | 0.7 | - |

| Apparent porosity | ≤ | % | 21 | 22 | 22 |

| True Density | ≤ | g/cm3 | 2.34 | 2.34 | 2.34 |

| 0.2MPa Load softening temperature | ≥ | ℃ | 1680 | 1670 | 1670 |

| Normal temperature compressive strength | ≥ | MPa | 40 | 35 | 30 |

| re-burn line change. 1450℃*2h | ≤ | % | 0.2 | 0.2 | 0.2 |

Silicon bricks offer excellent thermal stability, high refractoriness, and resistance to thermal shock, making them well-suited for use in glass kilns. The high silica content of these bricks provides them with good resistance to the corrosive effects of molten glass and other chemicals present in the kiln environment.

Characteristics and advantages:

High-temperature resistance: Silicon bricks can withstand temperatures well above 1500°C (2732°F). They retain their strength and structural integrity at high temperatures, making them suitable for the extreme conditions inside glass kilns.

Low thermal expansion: Silicon bricks have a relatively low coefficient of thermal expansion, which means they have minimal dimensional changes when exposed to rapid temperature variations. This property helps to reduce the risk of cracking or damage caused by thermal stress during heating and cooling cycles.

Resistance to thermal shock: Silicon bricks have excellent resistance to thermal shock, meaning they can withstand sudden temperature changes without cracking or spalling. This is important in glass kilns where quick temperature fluctuations can occur.

Good chemical resistance: Silicon bricks are highly resistant to the chemical attack of molten glass and other corrosive materials encountered in glassmaking processes. They can withstand the alkaline and acidic conditions found in the kiln without significant degradation.

Low porosity: Silicon bricks have a low porosity, which means they have a high density and are less prone to absorbing moisture or gases. This characteristic helps to maintain the structural integrity and stability of the bricks under high-temperature conditions.

Silicon bricks are typically used in the lining of various parts of glass kilns, including the furnace, regenerator chambers, and channels where the molten glass flows. They provide thermal insulation, prevent heat loss, and protect the kiln structure from the corrosive effects of the glass and high temperatures.

It's important to note that the exact composition and properties of silicon bricks can vary depending on the manufacturing process and intended application. Different additives and refractory materials may be incorporated to further enhance specific properties or address particular kiln requirements.

Tags :