Magnesia-chrome bricks are refractory products with magnesium oxide (MgO) and chromium trioxide (Cr2O3) as the main components, and periclase and spinel as the main mineral components. This type of magnesium-chrome brick has high refractory resistance, high high-temperature strength, strong resistance to alkaline slag erosion, excellent thermal stability, and certain adaptability to acidic slag. The main raw materials for manufacturing magnesia chrome bricks are sintered magnesia and chromite

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

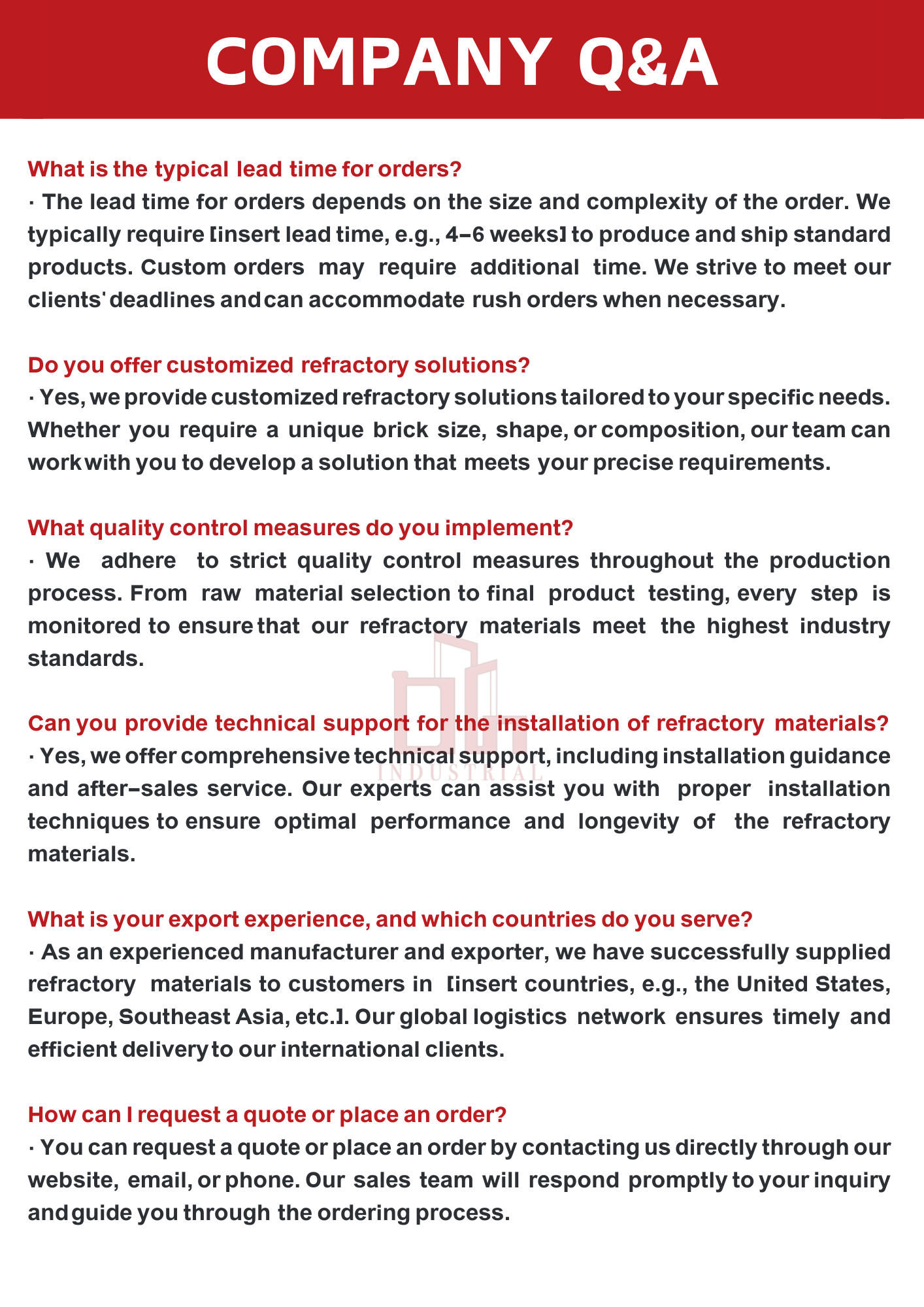

| Model | DYS-MGe6 | DYS-MGe8 | DYS-MGe12 | DYS-MGe16 | DYS-DMGe4 | DYS-DMGe8 | DYS-DMGe12 | DYS-DMGe16 |

| MgO % | 80 | 72 | 70 | 65 | 85 | 77 | 74 | 69 |

| Cr2O3 % | 7 | 10 | 13 | 17 | 5.5 | 9.1 | 14 | 18 |

| CaO % | 1.2 | 1.2 | 1.2 | 1.2 | 1.1 | 1.4 | 1.2 | 1.2 |

| SiO2 % | 3.4 | 4 | 4 | 4.2 | 1.3 | 1.2 | 1.2 | 1.5 |

| Al2O3 % | 4.5 | 6.5 | 6 | 6 | 3.5 | 4 | 3.5 | 4.5 |

| Fe2O3 % | 4 | 4.8 | 5.5 | 6.5 | 3 | 6.4 | 5 | 5.7 |

| Apparent Porosity % | 17 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| Bulk Density g/cm3 | 3 | 3 | 3.02 | 3.05 | 3.02 | 3.04 | 3.06 | 3.08 |

| Cold Crushing Strength Mpa | 55 | 55 | 55 | 50 | 50 | 50 | 55 | 55 |

| Refractoriness Under Load °C | 1600 | 1600 | 1600 | 1600 | 1700 | 1700 | 1700 | 1700 |

| Thermal expansion % 1000°C | / | / | / | / | 1 | 1 | 1 | 0.9 |

| Thermal expansion % 1600°C | / | / | / | / | 1.8 | 1.8 | 1.8 | 1.6 |

| Model | DYS-SRMGe16 | DYS-SRMGe18 | DYS-SRMGe20 | DYS-SRMGe22 | DYS-SRMGe26 | DYS-RMG0e12 | DYS-RMGe14 | |

| MgO % | 68 | 64 | 65 | 56 | 56 | 75 | 75 | |

| Cr2O3 % | 16 | 18 | 20 | 22 | 26 | 12 | 14 | |

| SiO2 % | 1.5 | 1.5 | 1 | 2.5 | 2.5 | 1.5 | 1.5 | |

| Apparent Porosity % | 16 | 16 | 14 | 16 | 16 | 15 | 15 | |

| Bulk Density g/cm3 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.2 | 3.2 | |

| Cold Crushing Strength Mpa | 40 | 40 |

40 |

40 | 40 | 50 | 50 | |

| Refractoriness Under Load °C | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | |

Magnesia-chromium bricks, also known as magnesia chrome bricks or MCr bricks, are a type of refractory brick commonly used in high-temperature industrial applications. They are composed mainly of magnesia (MgO) and chromium oxide (Cr2O3), with small amounts of other additives. These bricks possess several advantageous properties that make them suitable for demanding environments.

One of the key advantages of magnesia-chromium bricks is their excellent resistance to high temperatures. They can withstand temperatures up to 1800°C (3272°F) without significant deformation or structural damage. This makes them ideal for applications in industries such as steelmaking, cement production, non-ferrous metal refining, and glass manufacturing, where extreme heat is present.

Another advantage of magnesia-chromium bricks is their high corrosion resistance. The combination of magnesia and chromium oxide creates a protective layer of spinel (MgAl2O4) during firing, which acts as a barrier against chemical attack from molten slags, ashes, and corrosive gases. This resistance to corrosion ensures the longevity and reliability of the bricks in harsh environments, reducing the need for frequent maintenance and replacement.

Additionally, magnesia-chromium bricks exhibit good thermal shock resistance. They have a low coefficient of thermal expansion, meaning they can withstand rapid temperature changes without cracking or spalling. This property is crucial in applications where thermal cycling occurs, such as in furnaces and kilns, where the brick lining is exposed to alternating high and low temperatures.

Furthermore, magnesia-chromium bricks have high mechanical strength and abrasion resistance. They maintain their structural integrity even under heavy loads, minimizing the risk of structural failure or collapse. This is particularly important in industries that involve the handling of abrasive materials or mechanical stress, such as in the iron and steel industry.

Lastly, magnesia-chromium bricks have relatively good alkali resistance. They can withstand contact with alkaline materials, which can be detrimental to other types of refractory materials. This alkali resistance makes them suitable for applications in certain types of incinerators and waste treatment plants, where alkaline compounds and harsh chemicals may be present.

In conclusion, magnesia-chromium bricks offer numerous advantages in high-temperature industrial applications. Their excellent resistance to high temperatures, corrosion, thermal shock, mechanical stress, and alkali attack makes them a preferred choice for lining furnaces, kilns, and other equipment in various industries. The durability and reliability of magnesia-chromium bricks contribute to cost savings, as they require less frequent replacements and maintenance.

Tags :