Magnesite spinel bricks are refractory bricks made from a combination of magnesite (MgO) and spinel (MgAl2O4) minerals. These bricks are used in high-temperature applications where excellent thermal and chemical resistance is required, such as in the lining of steelmaking furnaces, cement kilns, and other industrial furnaces.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysStrength and Reliability for Your Toughest Challenges

Meet the demands of your high-temperature industrial processes with our Magnasite Spinel Bricks (B622). These bricks are engineered to perform exceptionally under the most intense conditions, offering high resistance to thermal shock, chemical attack, and mechanical stress. Whether you’re involved in steel production, cement manufacturing, or glass making, B622 bricks provide the robust performance and durability your operations require.

Key Features:

Why Choose B622?

Choose B622 for an industrial solution that delivers unmatched strength and reliability.

Data:

|

Apparent Porosity(%) |

15-18 |

|

Bulk Density (g/cm³) |

2.85-3.05 |

|

Cold Crushing Strength(MPa) |

45-85 |

|

Refractoriness under Load@Ta(°C) |

≥1700 |

|

Refractoriness under Load@Te(°C) |

≥1700 |

|

Thermal Shock resistance air (950°C) |

≥100 |

|

Thermal Conductivity(W/m.K)500°C |

4.0 |

|

Thermal Conductivity(W/m.K)1000°C |

2.9-3.0 |

|

Mgo(%) |

≥85 |

|

Al2O3(%) |

≥9 |

|

Fe2O3(%) |

≤0.5 |

|

SiO2(%) |

≤1.5 |

|

CaO(%) |

≤1.5 |

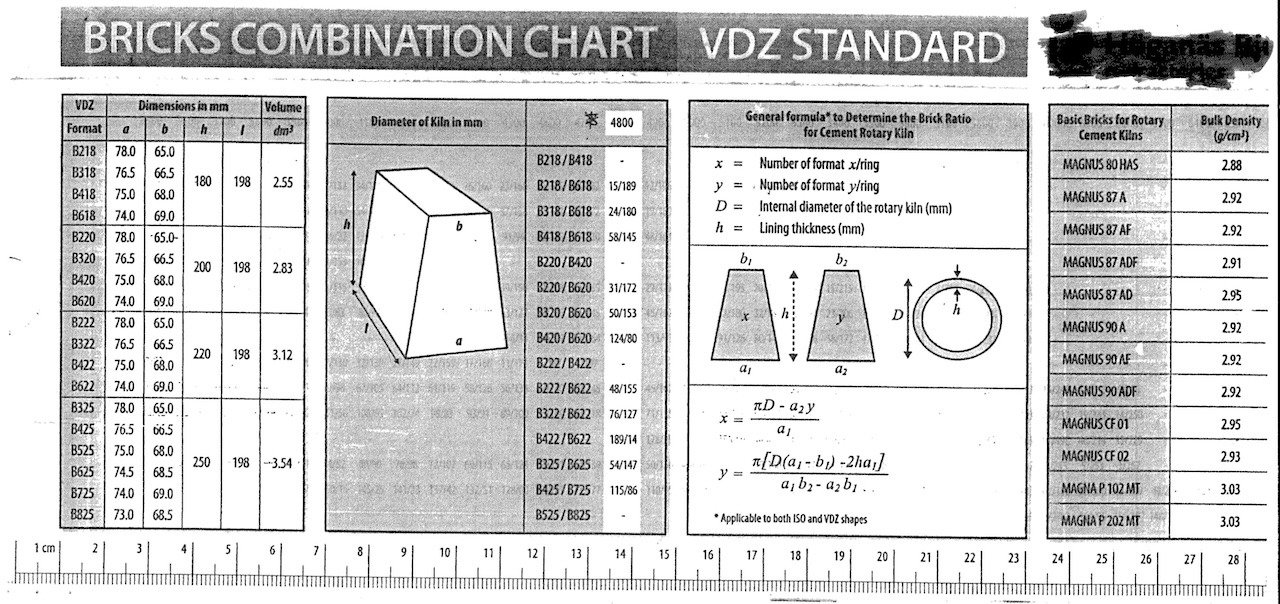

Size:

Frequently Asked Questions (FAQ)

Q1: What industries are best suited for Magnasite Spinel Bricks (B622)?

A1: B622 bricks are ideal for industries such as steelmaking, cement production, and glass manufacturing, where high resistance to thermal and chemical stress is critical.

Q2: What is the maximum temperature that B622 bricks can handle?

A2: These bricks are capable of withstanding temperatures up to 1700°, making them suitable for extreme heat applications.

Q3: How do B622 bricks compare to other refractory materials?

A3: B622 bricks offer superior durability and resistance to both thermal and chemical damage, providing a longer service life and more consistent performance than many other refractory materials.

Q4: Can B622 bricks be customized for specific furnace designs?

A4: Yes, our B622 bricks can be tailored to fit specific furnace designs. Please contact our technical team to discuss customization options.

Q5: What are the typical delivery times for B622 bricks?

A5: Delivery times vary depending on the order size and destination, but typically range from 15 days. For a precise estimate, please get in touch with our sales team.

Feel free to contact DYSen Industrial for Brick B622, We can produce according to your ingredient requirements.

Tags :