Magnesite spinel bricks are refractory bricks made from a combination of magnesite (MgO) and spinel (MgAl2O4) minerals. These bricks are used in high-temperature applications where excellent thermal and chemical resistance is required, such as in the lining of steelmaking furnaces, cement kilns, and other industrial furnaces.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysDiscover the ultimate in high-temperature performance with our Magnasite Spinel Bricks (B325). Specifically engineered to thrive in the most demanding industrial conditions, these bricks provide exceptional resistance to thermal shock, corrosion, and mechanical wear. Whether your operations involve steelmaking, cement kilns, or glass production, our B325 bricks are the backbone your furnaces need, ensuring durability, efficiency, and long-term savings.

Key Features:

Why Choose B325?

Elevate your operations with the strength and reliability of our Magnasite Spinel Bricks—crafted to keep your business running smoothly.

Data:

|

Apparent Porosity(%) |

15-18 |

|

Bulk Density (g/cm³) |

2.85-3.05 |

|

Cold Crushing Strength(MPa) |

45-85 |

|

Refractoriness under Load@Ta(°C) |

≥1700 |

|

Refractoriness under Load@Te(°C) |

≥1700 |

|

Thermal Shock resistance air (950°C) |

≥100 |

|

Thermal Conductivity(W/m.K)500°C |

4.0 |

|

Thermal Conductivity(W/m.K)1000°C |

2.9-3.0 |

|

Mgo(%) |

≥85 |

|

Al2O3(%) |

≥9 |

|

Fe2O3(%) |

≤0.5 |

|

SiO2(%) |

≤1.5 |

|

CaO(%) |

≤1.5 |

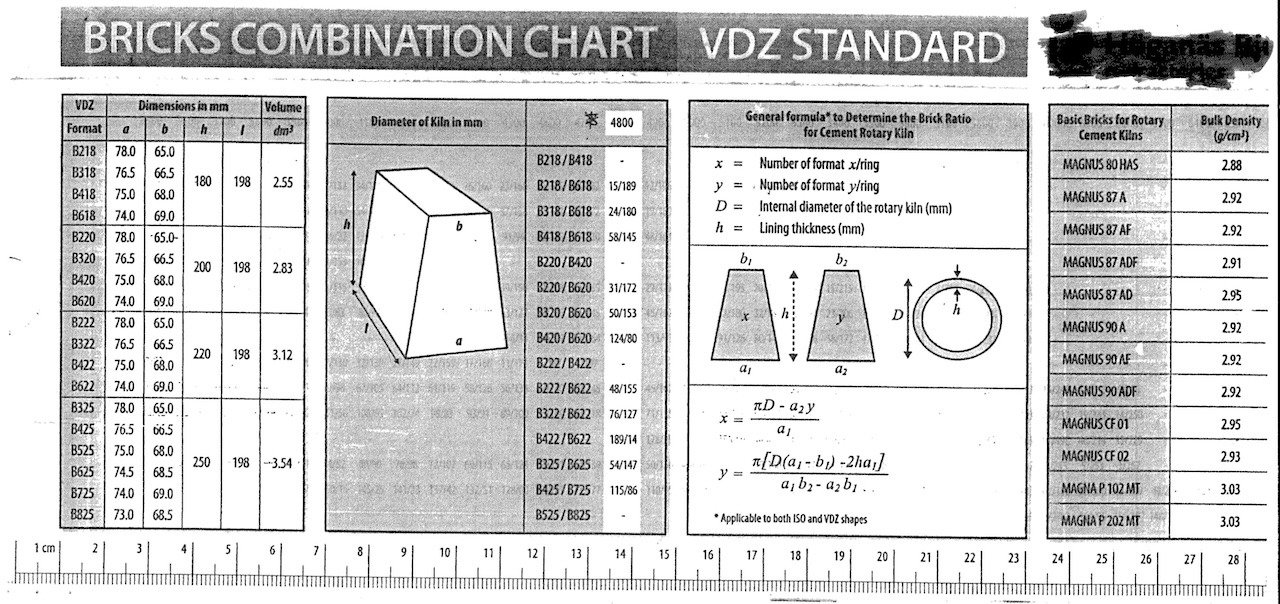

Size:

Frequently Asked Questions (FAQ)

Q1: What are the typical applications for Magnasite Spinel Bricks (B325)?

A1: The B325 bricks are commonly used in high-temperature industrial processes, including steelmaking furnaces, cement kilns, and glass manufacturing. Their high resistance to heat and corrosion makes them suitable for any environment where refractory materials are required.

Q2: What is the maximum operating temperature for these bricks?

A2: Our Magnasite Spinel Bricks are designed to withstand temperatures up to 1700°, making them perfect for extreme heat applications.

Q3: How do these bricks compare to other refractory materials?

A3: Compared to other refractory materials, the B325 offers superior resistance to thermal shock and chemical corrosion, resulting in a longer lifespan and more reliable performance under extreme conditions.

Q4: Can I use these bricks in an existing furnace without modifications?

A4: Yes, our Magnasite Spinel Bricks are designed to fit standard industrial furnaces. However, we recommend consulting with our technical team to ensure optimal performance based on your specific furnace design.

Q5: What is the typical delivery time for an order?

A5: Delivery times can vary depending on the order size and destination. Typically, orders are processed and shipped within 15 days. Please contact our sales team for a more accurate delivery estimate.

Tags :