Refractory cement, also known as refractory castable, is a special type of cement that is designed to withstand high temperatures and perform well in applications that involve extreme heat. It is commonly used in various industries, including steelmaking, foundries, cement plants, boilers, and furnaces.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysRefractory cement is formulated with a combination of refractory aggregates (such as alumina, silica, or magnesia) and a binder system that can withstand high temperatures. The aggregates provide the material with heat resistance and mechanical strength, while the binder system helps to hold the aggregates together.

Key characteristics:

High heat resistance: Refractory cement is designed to withstand extremely high temperatures, typically in the range of 1300°C to 1800°C (2372°F to 3272°F) or even higher.

Excellent thermal shock resistance: It can resist sudden temperature changes without cracking or spalling, which is crucial in applications where rapid temperature fluctuations occur.

Good workability: Refractory cement can be poured, cast, or gunned into various shapes and forms to suit specific applications. It can be easily mixed and applied using standard construction techniques.

Chemical resistance: Refractory cement is resistant to chemical attack from materials such as acids, alkalis, and slags, making it suitable for harsh environments.

The specific formulation of refractory cement can vary depending on the intended application and temperature requirements. Different types of aggregates and binders can be used to tailor the properties of the cement to the desired level of heat resistance, strength, and durability.

It's important to follow the manufacturer's instructions for mixing, curing, and firing temperatures specific to the refractory cement being used, as proper installation and curing procedures are crucial for achieving the desired performance and longevity.

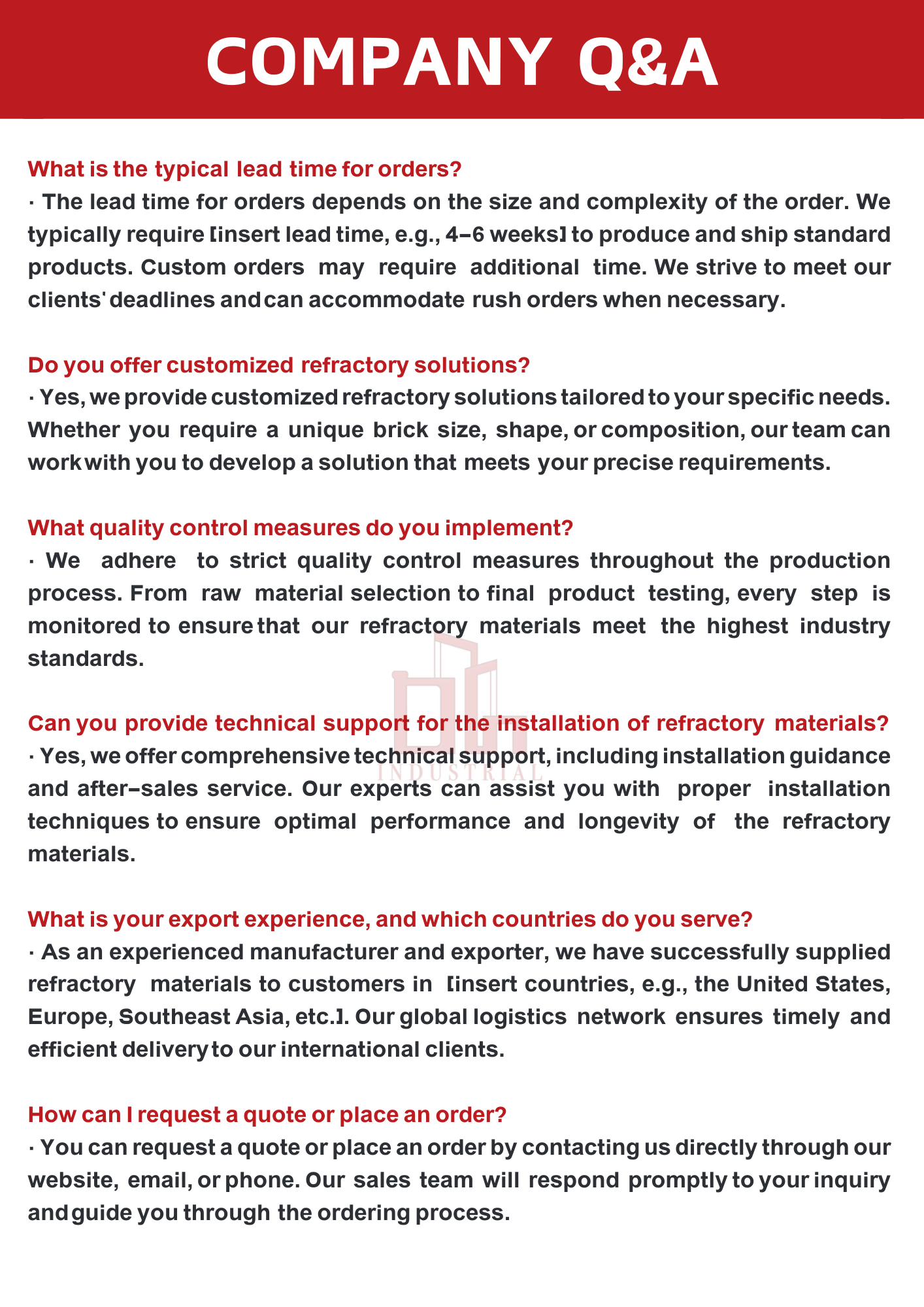

Product parameters:

| Products | DM75 | DM75 | DM80 | DM80 | DM80S | DM80S |

| Workable time | Moderate | Moderate | Short | Short | Longer | Longer |

| Standard | Usual range | Specification limit | Usual range | Specification limit | Usual range | Specification limit |

| SiO2, % | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 |

| Al2O3, % | 73.5-75.5 | ≥73 | 78.0-80.0 | ≥77 | 78.0-80.0 | ≥77 |

| Fe2O3, % | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 |

| CaO, % | 21.0-23.0 | - | 18.5-20.5 | - | 18.5-20.5 | - |

| R2O, % | - | ≤0.4 | - | ≤0.4 | - | ≤0.4 |

| S-, % | - | ≤0.1 | - | ≤0.1 | - | ≤0.1 |

| CI-, % | - | ≤0.06 | - | ≤0.06 | - | ≤0.06 |

| d50(μm) | 45086 | ≤10 | 45054 | ≤9 | 45054 | ≤9 |

| 325M(%) | - | ≤5.0 | - | ≤5.0 | - | ≤5.0 |

| Specific surface areas(㎡/kg) | 420-480 | ≥400 | 450-500 | ≥450 | 450-500 | ≥450 |

| Setting time, min | ||||||

| Initial setting time IS | 150-200 | ≥150 | 150-210 | ≥30 | 210-270 | ≥180 |

| Final setting time FS | 240-300 | ≤360 | 210-270 | ≤300 | 260-320 | ≤360 |

| Flexural strength, Mpa | ||||||

| 1d | 6.5-8.5 | ≥4.0 | 6.0-8.0 | ≥4.0 | 5.5-7.5 | ≥4.0 |

| 3d | 8.5-10.5 | ≥5.0 | 7.0-9.0 | ≥5.0 | 7.0-9.0 | ≥5.0 |

| Compressive strength, Mpa | ||||||

| 1d | 42-52 | ≥25 | 40-50 | ≥25 | 35-45 | ≥25 |

| 3d | 52-62 | ≥30 | 50-60 | ≥30 | 50-60 | ≥30 |

If you need technical assistance, please feel free to contact us. Basic usage of refractory cement.