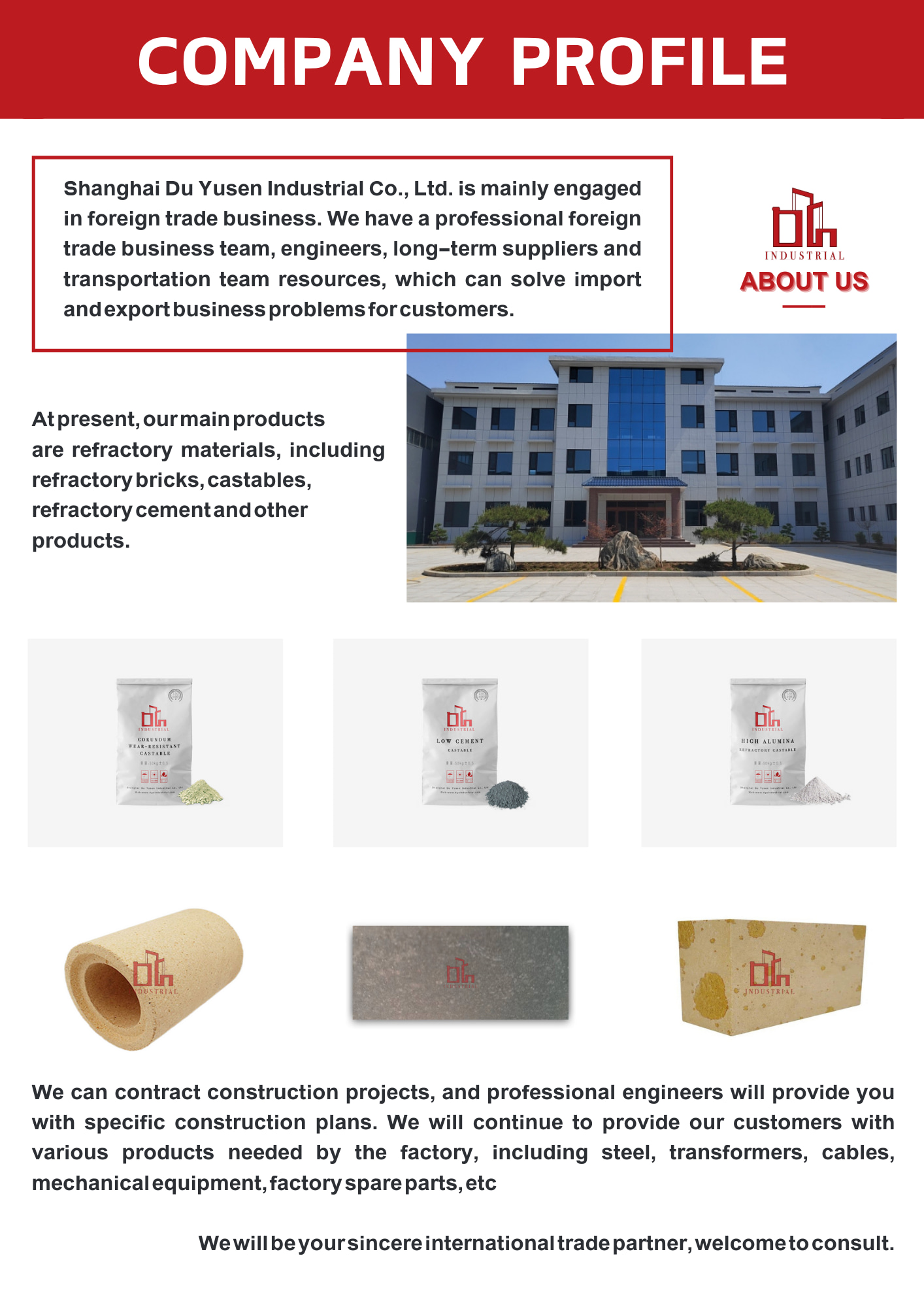

Bauxite is a naturally occurring ore that serves as the primary source of aluminum. It is a mixture of various hydrated aluminum oxides, clay minerals, and impurities, with the main constituent being the mineral gibbsite (Al(OH)3). Bauxite deposits are typically found in tropical or subtropical regions.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

| Grade | Al2O3 | CaO | Fe2O3 | Refractoriness | Bulk Density |

| premium | >85 | <0.6 | <1.4 | >1790℃ | >3.6g/cm3 |

| Grade A | >80 | <0.6 | <3.0 | >1790℃ | >3.0g/cm3 |

| Grade B+ | 70-80 | <0.8 | <3.0 | >1790℃ | >2.8g/cm3 |

| Grade B | 60-70 | <0.8 | <3.0 | >1770℃ | >2.65g/cm3 |

| Grade C | 50-60 | <0.8 | <2.5 | >1770℃ | >2.55g/cm3 |

The formation of bauxite occurs through weathering and leaching processes over millions of years. The parent rock, usually granite or basalt, undergoes chemical and physical weathering, resulting in the release of aluminum and silica. These elements, along with other impurities, are transported by water and accumulate in low-lying areas, such as river valleys or sedimentary basins, where bauxite deposits form.

The composition of bauxite can vary, but it generally contains around 30% to 60% alumina (aluminum oxide, Al2O3) along with varying amounts of iron oxide, silica, and other impurities such as titanium dioxide, organic matter, and clay minerals. The presence of these impurities affects the quality and suitability of bauxite for aluminum production.

Bauxite is the primary raw material used in the production of alumina, which is further processed to obtain pure aluminum metal through the Hall-Héroult process. The extraction of alumina from bauxite involves a series of steps that include mining, crushing, beneficiation (removal of impurities), and refining.

Refractories: Bauxite with high alumina content and low impurities is used in the manufacture of refractory materials, including refractory bricks and castables, primarily in the steel, cement, and glass industries.

Abrasives: Calcined bauxite, which is bauxite heated at high temperatures, is used as a high-quality abrasive material in applications such as sandblasting, grinding, and polishing.

Chemicals: Bauxite can be processed to extract other valuable minerals and materials. For example, it can be used as a source of aluminum sulfate, which is used in water treatment, paper manufacturing, and various chemical processes.

Cement industry: Bauxite with a high alumina and low iron content is used as an additive in cement production to enhance its properties, such as strength and durability.

Bauxite is a valuable resource due to its aluminum content, and its mining and processing have social, economic, and environmental implications. Sustainable practices and environmental considerations are important in the bauxite mining industry to minimize the impact on the surrounding ecosystems and communities.