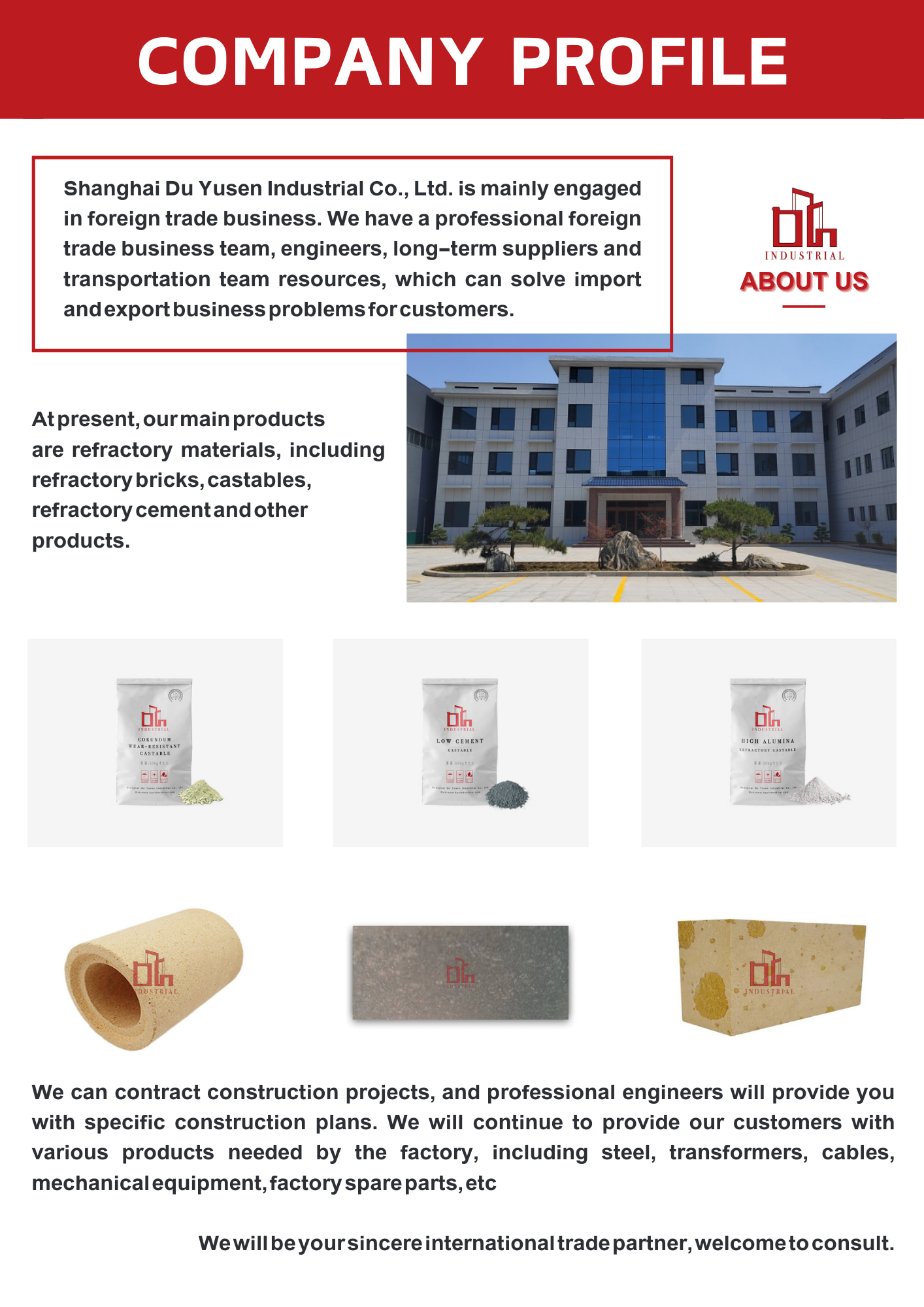

Camic fiber tube, also referred to as ceramic fiber sleeve or ceramic fiber pipe, is a tubular refractory product made from high-purity ceramic fibers. It is designed to provide thermal insulation and protection in high-temperature applications.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysKey features and benefits:

Thermal insulation: Ceramic fiber tubes offer excellent thermal insulation properties, reducing heat transfer and maintaining temperature stability in high-temperature environments.

High-temperature stability: Ceramic fiber tubes can withstand continuous exposure to high temperatures, typically up to 2300°F (1260°C) or higher, depending on the specific product.

Lightweight and low density: Ceramic fiber tubes have a low density, making them lightweight and easier to handle and install compared to traditional refractory materials. They help reduce the overall weight and structural load on equipment.

Chemical stability: Ceramic fiber tubes are chemically inert and resistant to most acids, alkalis, and organic solvents. They are stable in corrosive environments, maintaining their structural integrity and insulation properties.

Resistance to thermal shock: Ceramic fiber tubes exhibit good resistance to thermal shock, enabling them to withstand rapid temperature changes without cracking or breaking.

Versatility: Ceramic fiber tubes can be used in a variety of applications, including as a protective sleeve for thermocouples and heating elements, as insulation for pipes, as part of kiln or furnace linings, and in other high-temperature equipment.

Ceramic fiber tubes are available in different sizes, thicknesses, and densities to suit various applications. They can be custom cut or fabricated to meet specific requirements. When using ceramic fiber tubes, it is important to follow safety guidelines and handle them with care to minimize the release of airborne fibers. Taking appropriate precautions, such as using personal protective equipment and working in well-ventilated areas, is recommended.

Product parameters:

| Type | ASFT-1 | ASFT-2 |

| Service temperature, ℃ | 1000 | 1260 |

| B.D, kg/m3 | 100-180 | 150-300 |

| Thermal conductivity | 0.034(20℃) | 0.127(600℃) |

| w/(m·k) | 0.09(400℃) | 0.20(1000℃) |

| 0.12(600℃) | ||

| Shot content, %, Φ>0.25mm | 11 | 13.6 |

| Permanent liner change, % | 3.5 | 2 |

| (After 24 hours) | 600℃ | 1000℃ |

Tags :