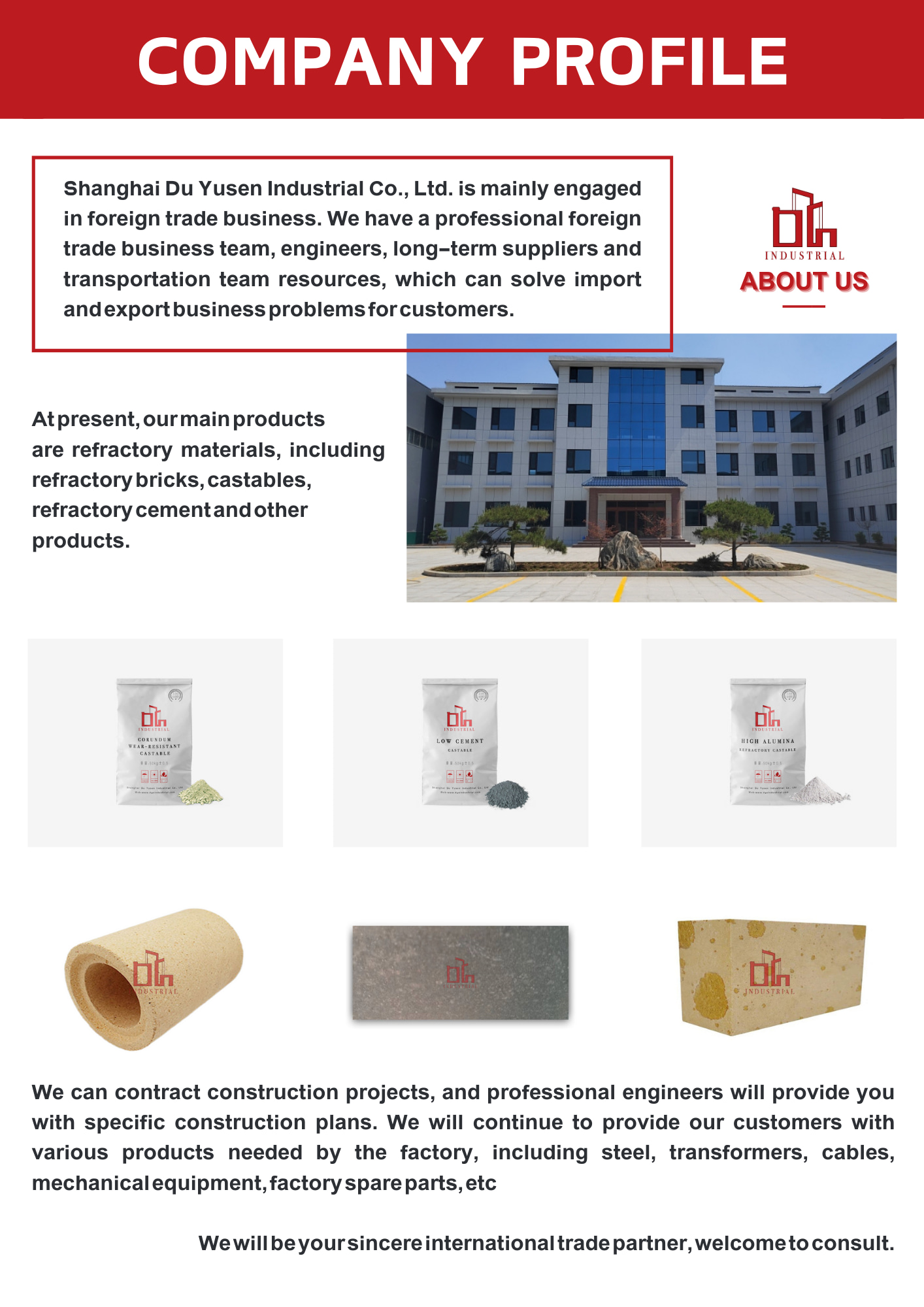

Ceramic fiber board is a type of lightweight refractory material that is made from ceramic fibers and binders. It is known for its excellent thermal insulation properties and is widely used in high-temperature applications where heat containment and energy efficiency are critical.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysCeramic fiber boards are composed of alumina-silica fibers, which are formed into a rigid board through a combination of wet forming and vacuum molding processes. The fibers are held together by binders, typically organic or inorganic additives, which provide strength and structural integrity to the board.

Key features and benefits of ceramic fiber boards:

Thermal insulation: Ceramic fiber boards have high thermal insulation properties, allowing them to effectively reduce heat transfer. They have low thermal conductivity, which means they can minimize energy loss and maintain temperature stability in applications such as furnaces, kilns, and heat processing equipment.

Lightweight: Ceramic fiber boards are lightweight compared to traditional refractory materials like bricks and castables. This makes them easier to handle, transport, and install, reducing labor and construction time.

Low heat storage: Ceramic fiber boards have low heat storage capacity, enabling faster heat-up and cool-down cycles. This can enhance the energy efficiency of heating equipment and improve process control.

Excellent resistance to thermal shock: Ceramic fiber boards can withstand rapid temperature changes without cracking or spalling. This makes them suitable for applications where thermal shock is common, such as in furnace linings or in areas near burner flames.

Chemical stability: Ceramic fiber boards have good chemical resistance to most acids, alkalis, and organic solvents. They are not easily attacked by chemicals, which allows them to maintain their integrity and insulation properties even in harsh environments.

Machinability: Ceramic fiber boards can be easily cut, shaped, and drilled to fit specific dimensions and requirements. This flexibility in fabrication allows for customization and precise installation in various thermal insulation applications.

Ceramic fiber boards find applications in a wide range of industries, including steel, petrochemical, ceramics, power generation, and aerospace. They are commonly used for furnace linings, kiln insulation, thermal barriers, expansion joint seals, and other heat containment applications.

When handling ceramic fiber boards, it's important to follow proper safety precautions as the fibers can cause skin and respiratory irritation. Personal protective equipment, such as gloves and masks, should be used to minimize exposure to the fibers.

Product parameters:

| Type | Ordinary | Standard | High Purity | High Alumina | Zirconium |

| Classification temperature, ℃ | 1100 | 1260 | 1260 | 1360 | 1430 |

| Working temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Colour | white | Pure white | Pure white | Pure white | Pure white |

| B.D, kg/m3 | 260-320 | 260-320 | 260-320 | 260-320 | 260-320 |

| PERMANENT liner change, % | -4 | -3 | -3 | -3 | -3 |

| 24Hours under ,B.D320kg/m3 | (1000℃) | (1000℃) | (1100℃) | (1250℃) | (1350℃) |

| HEAT CONDUCTIVITY COEFFICIENT | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) |

| w/m·k | |||||

| B.D, 285kg/m3 | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) |

| B.D, 285kg/m3 | 0.180(1000℃) | 0.180(1000℃ ) | 0.180(1000℃) | 0.180(1000℃) | 0.180(1000℃) |

| STRENGTH EXTENSION, Mpa, | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| THICKNESS SHRINKAGE 10% | |||||

| Al2O3 | 0.44 | 0.46 | 47~49% | 52~55% | 39~40% |

| Al2O3+SiO2 | 0.96 | 0.97 | 0.99 | 0.99 | - |

| Al2O3+SiO2+ZrO2 | - | - | - | - | 0.99 |

| ZrO2 | - | - | - | - | 15~17% |

| Fe2O3 | <1.2% | <1.0% | 0.002 | 0.002 | 0.002 |

| Na2O+K2O | ≤0.5% | ≤0.5% | 0.002 | 0.002 | 0.002 |

Tags :