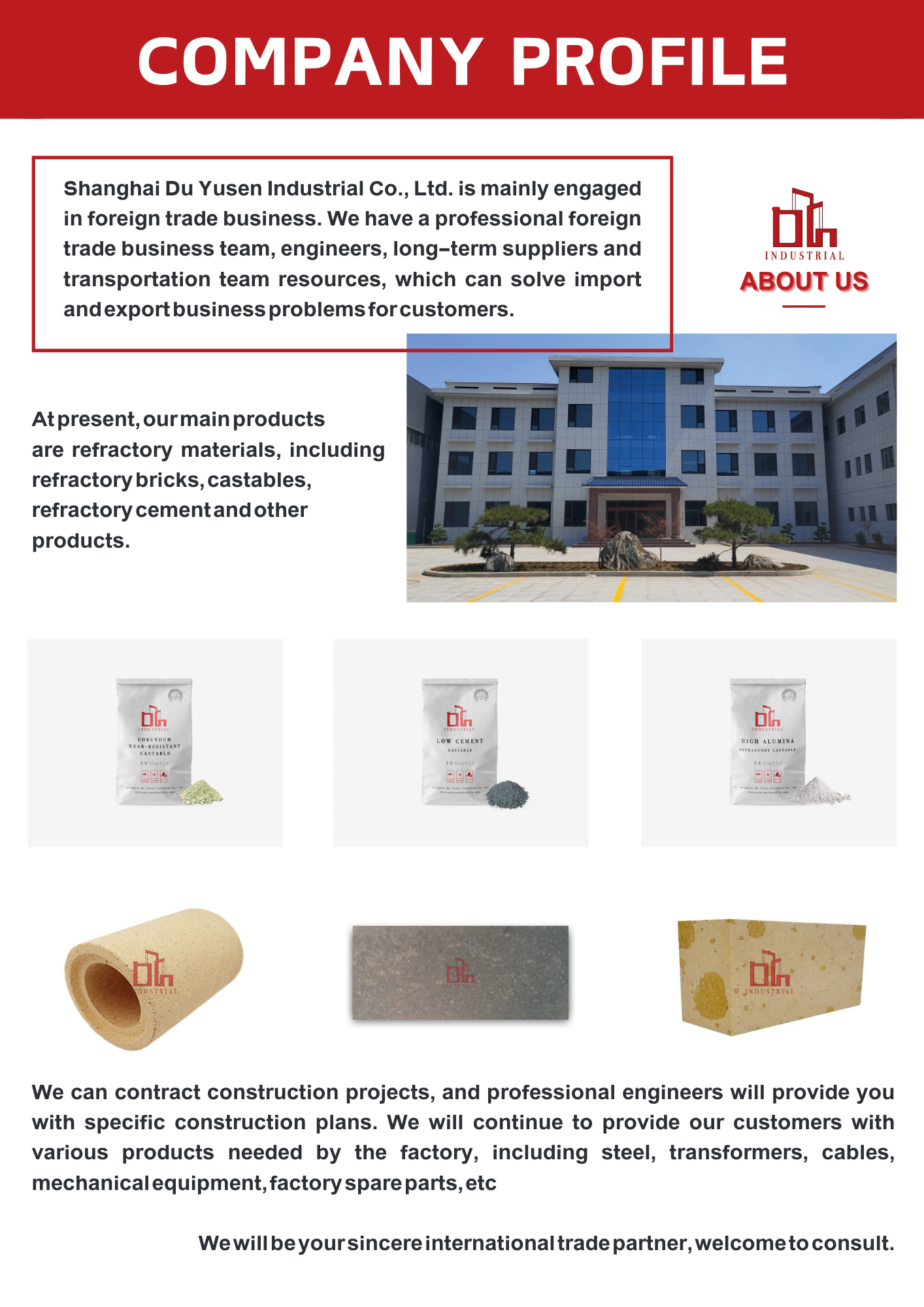

Silica refractory balls are spherical refractory materials made from high-purity silica. They are commonly used in high-temperature applications, such as in the lining of furnaces, kilns, and other thermal processing equipment.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysSilica refractory balls are spherical refractory materials made from high-purity silica. They are commonly used in high-temperature applications, such as in the lining of furnaces, kilns, and other thermal processing equipment.

Silica refractory balls have excellent thermal stability and resistance to thermal shock, making them ideal for use in environments with severe temperature fluctuations. They can withstand temperatures up to 1650 degrees Celsius (3002 degrees Fahrenheit) without significant structural degradation.

These refractory balls are known for their low thermal conductivity, which helps to reduce heat loss and improve energy efficiency in applications where insulation is required. Their high strength and abrasion resistance make them suitable for use in harsh conditions and environments with chemical corrosion.

Silica refractory balls also have good resistance to alkalis and acids, making them suitable for applications involving contact with various chemical substances. They are often used in the petrochemical industry, where they are employed as catalyst support media in catalytic cracking and other refining processes.

In addition, silica refractory balls are lightweight and have a high crushing strength, which allows for easy handling and installation. Their uniform shape and size provide good packing density, ensuring optimal heat transfer and efficient thermal insulation.

Overall, silica refractory balls offer a reliable and durable solution for high-temperature applications that require thermal insulation, chemical resistance, and mechanical strength.