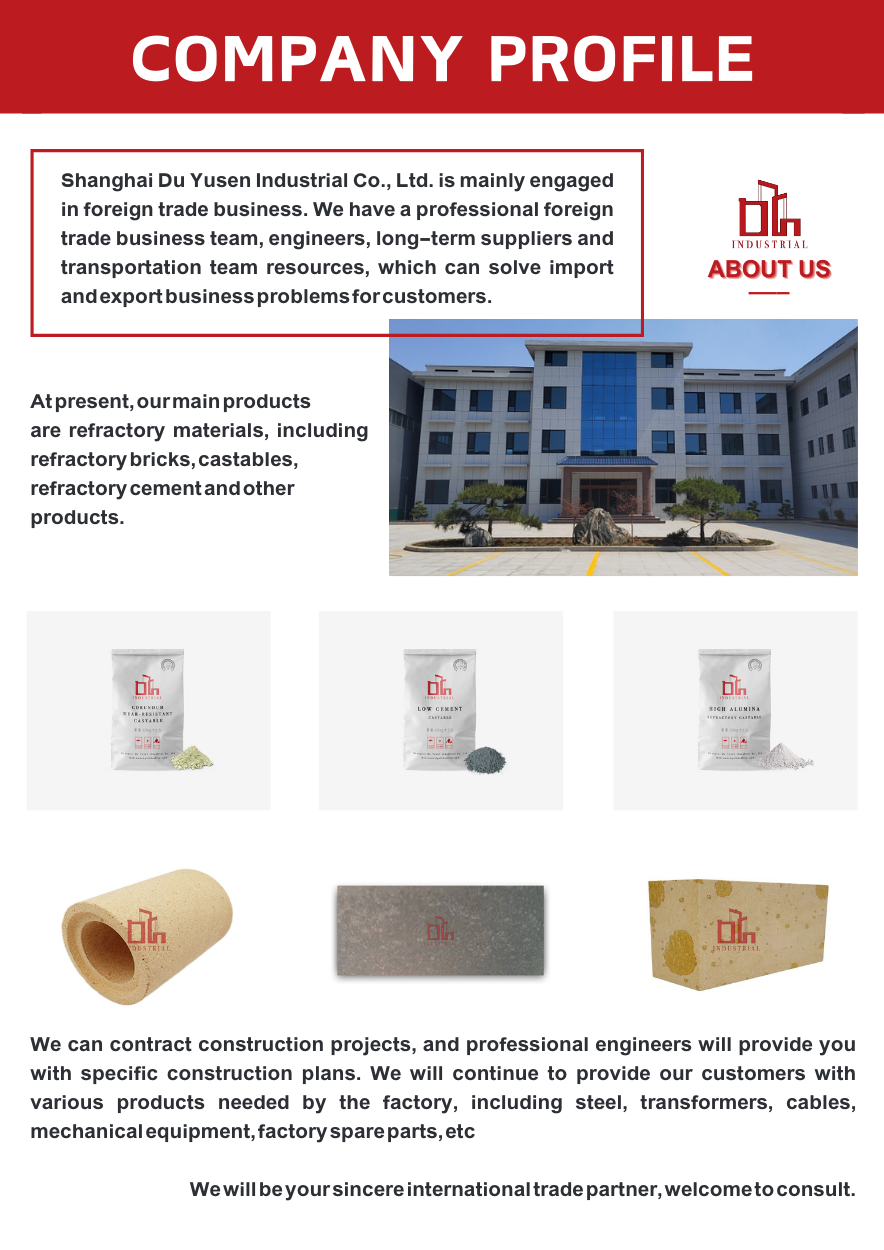

Lightweight silica insulation brick is a type of refractory brick used for high-temperature insulation applications. It is made from high-purity silica combined with a lightweight aggregate and a binder to create a lightweight and thermally efficient material.

The lightweight aggregate used in the production of silica insulation bricks helps to reduce the density of the material, making it lighter and easier to handle. The aggregate can vary but commonly includes materials such as expanded perlite, vermiculite, or lightweight clay. The choice of aggregate depends on factors such as desired insulation properties and application requirements.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

| Item | DYSQG-1.0 | DYSQG-1.1 | DYSQG-1.2 |

| SiO2 % | 91 | 91 | 91 |

| Refractoriness°C | 1680 | 1680 | 1670 |

| 0.2Mpa Refractoriness Under Load °C | 1480 | 1560 | 1560 |

| Cold Crushing Strength Mpa | 3.5 | 3.5 | 3.5 |

| True Density g/cm3 | 2.39 | 2.39 | 2.39 |

| Bulk Density g/cm3 | 1 | 1.1 | 1.2 |

| Permanent Linear Change On Reheating(%) | 0~+0.5 | 0~+0.5 | 0~+0.5 |

| 1450°CX2h | 1550°CX2h | 1550°CX2h | |

| Thermal Conductivity (W/MK) 350°C | 0.55 | 0.6 | 0.65 |

Applications of bricks:

Lightweight silica insulation bricks are commonly used in various industries, including glass, ceramics, metallurgy, petrochemicals, and other high-temperature applications. They provide excellent thermal insulation, reduce heat loss, and help maintain high temperatures in industrial furnaces, kilns, and other thermal processes. Additionally, their lightweight nature makes them easier to install and handle compared to denser refractory materials.

These bricks also offer good resistance to chemical attack, which is beneficial in applications where corrosive gases or chemicals are present. They have a low coefficient of thermal expansion, meaning they can withstand thermal cycling without cracking or spalling.

Tags :