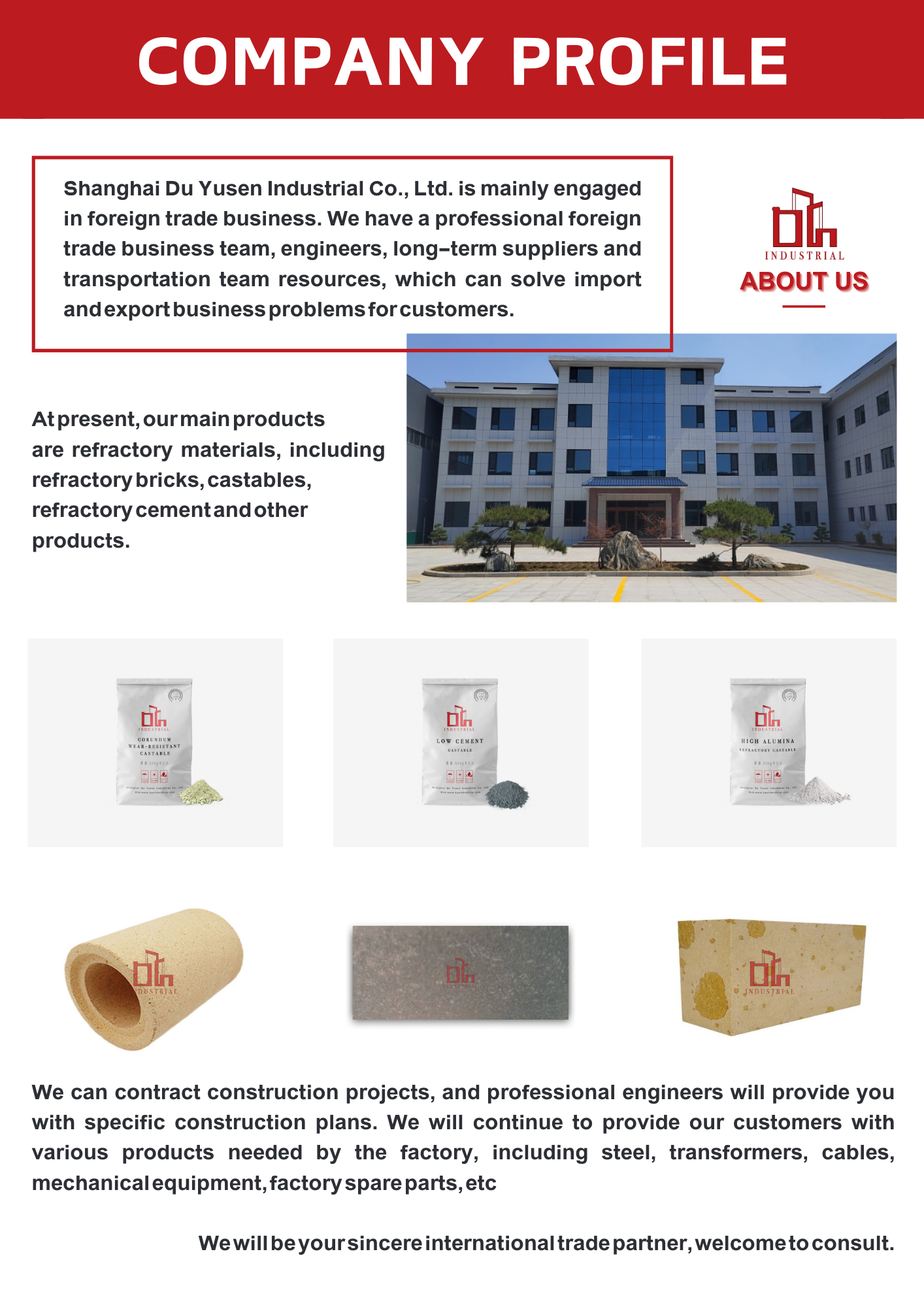

Clay bricks generally have an Al2O3 content of over 40% and an Fe2O3 content less than 2.0-2.5%. The raw material mixture consists of 65-85% clinker and 35-15% bonding clay. The crushed bonding clay and finely ground clinker are mixed and milled together, then formed under high pressure to produce a semi-dry mud. This mixture is fired at around 1400°C, resulting in good performance. Clay bricks exhibit a weak acidic nature at high temperatures and have a slightly lower resistance to alkaline slag erosion, but this ability improves with higher Al2O3 content. They have better thermal stability compared to silica bricks and magnesia bricks.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

| Item/Grade | DYSFCB-30 | DYSFCB-32 | DYSFCB-34 | DYSFCB-35 |

| Al2O3% (≥) | 30 | 35 | 38 | 45 |

| Fe2O3% (≤) | 2.5 | 2.5 | 2 | 2 |

| Refractoriness(SK) | 30 | 32 | 34 | 35 |

| Refractoriness underload, 0.2MPa, °C (≥) | 1250 | 1300 | 1360 | 1420 |

| Apparent porosity (%) | 22-26 | 20-24 | 20-22 | 18-20 |

| Bulk density (g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 |

| Cold crushing strength ,MPa (≥) | 40 | 45 | 30 | 40 |

Product Feature and Application:

Fire Clay bricks are durable and have the advantages of fire protection, heat insulation, sound insulation, and moisture absorption. They are widely used in civil construction projects. Waste bricks can also be used as concrete aggregates. In order to improve the shortcomings of ordinary clay bricks that are small, heavy, and consume a lot of land, they are developing in the direction of being lightweight, high-strength, hollow, and large. Lime sand bricks are made of appropriate proportions of lime and quartz sand, sand or fine sandstone, which are ground, mixed with water, pressed in a semi-dry method and cured by autoclaving. Fly ash bricks use fly ash as the main raw material, mixed with coal gangue powder or clay and other cementing materials, and are made through batching, shaping, drying and roasting. They can make full use of industrial waste and save fuel.

Clay bricks can also be used in glass kilns.

Tags :