Causes And Solutions Of Damage To Refractory Bricks In The Transition Zone Of Cement Kilns

Jan 03, 2024In the cement kiln transition zone, refractory materials are subject to corrosion and pressure from all aspects during use, resulting in a service life that is usually 40% lower than that in the firing zone.

1. Cause of damage

1. Effect of high temperature

The ambient temperature in the transition zone is relatively high. The material temperature here is 1000℃~1300℃ and the gas temperature is 1400℃~1600℃. Although the material is fully heated after entering the kiln, it fails to reach the fired state and is affected by the firing zone. , the transition zone is in a thermally unstable state, and the kiln skin wears off over time, causing the kiln lining to be directly exposed to high temperature environments.

2. Chemical attack

Volatile components such as the melt in the cement clinker and the silicate low melts in the coal ash, K2O, SO2, KCl directly erode and penetrate into the surface of the refractory bricks. Under the action of the temperature gradient and the concentration gradient of the erosion layer, the structure The layer changes. As time goes by and the temperature field changes, the metamorphic structural layer is prone to cracking and falling off.

3. Coal injection pipe and fuel changes

3. Coal injection pipe and fuel changes

The temperature field in the transition zone is easily affected by changes in the coal injection pipe and fuel and continues to change.

The flame shape of the coal injection pipe is affected by the particle size of the coal powder, ash powder composition, volatile matter content and ejection speed. Improper adjustment of the air inside and outside the coal injection pipe, too high wind pressure of the coal supply fan, too low secondary air temperature, etc. will cause the pulverized coal burning speed to be lower than the advancing speed of the pulverized coal particles in the kiln, which will lead to afterburning of the pulverized coal and lead to thermal engineering. Unstable.

Refractory materials are prone to thermal fatigue when they undergo repeated temperature field changes. Generally, materials cannot withstand the rapid cooling and rapid heating caused by temperature field changes, resulting in damage to the transition zone lining bricks.

4. Mechanical force

Since the rotary kiln cylinder has a certain inclination between the supporting points, as the rotary kiln operates, periodic bending will occur synchronously with the rotation.

The rotary kiln with three groups of tugs adopts a statically indeterminate structure. When each tug group has different expansion amounts due to temperature differences, the coaxiality of the kiln barrel will deviate, resulting in a large additional load. Especially in bad weather or sudden power outage, the kiln barrel will undergo greater bending and deformation due to uneven heating up and down, causing the refractory bricks in the kiln to bear greater extrusion stress. When the bearing capacity of the refractory material is exceeded, the refractory material will appear. Broken or even completely displaced.

2. Solution

2. Solution

1. Aiming at the influence of high temperature

① Optimize the gas flow in the kiln: Change the air flow distribution or install baffles and other measures to better discharge and disperse the high-temperature gas near the transition zone.

② Control the materials entering the kiln: By adjusting the feed amount, feed speed and ratio in the kiln, the materials can be fully sintered before entering the transition zone.

③ Strengthen kiln lining protection measures: Select kiln lining materials with high fire resistance and design appropriate thickness to enhance its ability to resist high temperature erosion.

2. Coping strategies affected by chemical attack

① Choose refractory materials with good corrosion resistance: Choose refractory materials with strong chemical stability and corrosion resistance to reduce the degree of corrosion by chemical substances.

② Control the atmosphere in the kiln: adjust the oxygen content, atmosphere composition and combustion temperature in the kiln to control the generation and concentration of harmful gases and reduce the erosion of refractory bricks.

③ Regularly clean the slag and residue accumulated in the kiln to reduce its erosion of refractory materials. At the same time, regular inspection and maintenance are carried out to promptly repair damaged parts and extend the service life of refractory materials.

④ By monitoring parameters such as temperature, atmosphere and chemical composition in real time, the operating conditions of the kiln can be adjusted in a timely manner to maintain a stable combustion and production environment and reduce the risk of chemical erosion.

3. Response strategies to changes in coal injection pipes and fuel

① Use high-quality coking coal to reduce the content of sulfur and other harmful components. The ash content is less than 27%, the volatile content is greater than 25%, the calorific value is greater than 21MJ/kg (more than 5000 kcal/kg)/, and the total sulfur is less than 3%. Gas coal, weakly sticky coal, non-sticky coal, etc.

② Control the air adjustment inside and outside the coal injection pipe, and monitor the flame shape and length of the coal injection pipe.

The extension part of the coal injection pipe should ideally be 1 to 1.5 meters beyond the discharge opening. Within this range, the mixture of air and coal is optimal, the flame is complete, the inside of the kiln is clear and easy to see, the operation is easy to control, and the front ring position of the knot is also easy to burn.

4. Countermeasures against the influence of mechanical forces

① Use materials with high strength and good thermal expansion resistance to reduce problems caused by different expansion amounts caused by temperature differences.

② Adjust the wheel belt gap to the appropriate width. During the operation of the kiln, regularly inspect and maintain the tug wheel components to ensure the coaxiality and smooth operation of each group of tug wheels.

In summary, among the methods for reducing refractory damage in the transition zone, the methods that can be solved through manual intervention include optimizing gas flow, controlling the atmosphere in the kiln, regularly cleaning slag, using high-quality coal, controlling the indicators of materials entering the kiln, and controlling Matching of wind, coal and materials. For those phenomena that are difficult to control in production, adjusting the transition zone kiln body refractory material is a crucial step in solving the problem.

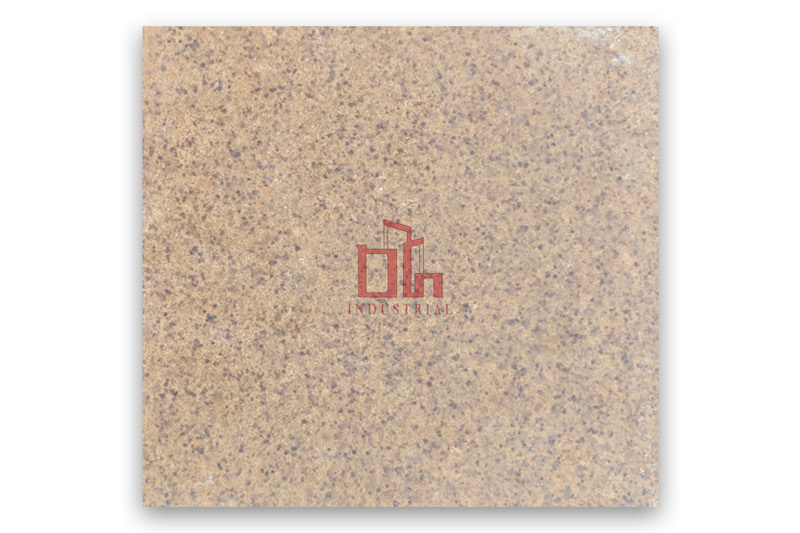

Considering the special working conditions of the cement kiln transition zone with poor thermal stability, serious chemical erosion, and susceptible to the influence of fuel and coal injection pipes, one of the more commonly used alkaline refractory materials at present is magnesia-aluminum spinel refractory bricks.