The raw materials of aluminum-magnesium castables for ladles are basically the same as aluminum-magnesium refractory ramming materials. In order to obtain room temperature strength, sodium fluorosilicate should be added as a coagulant. The load softening temperature of ladle aluminum-magnesium castable is lower, which is due to the combination of some low-baking substances formed by adding magnesia powder and the interaction between water glass and sodium fluorosilicate.

Payment :

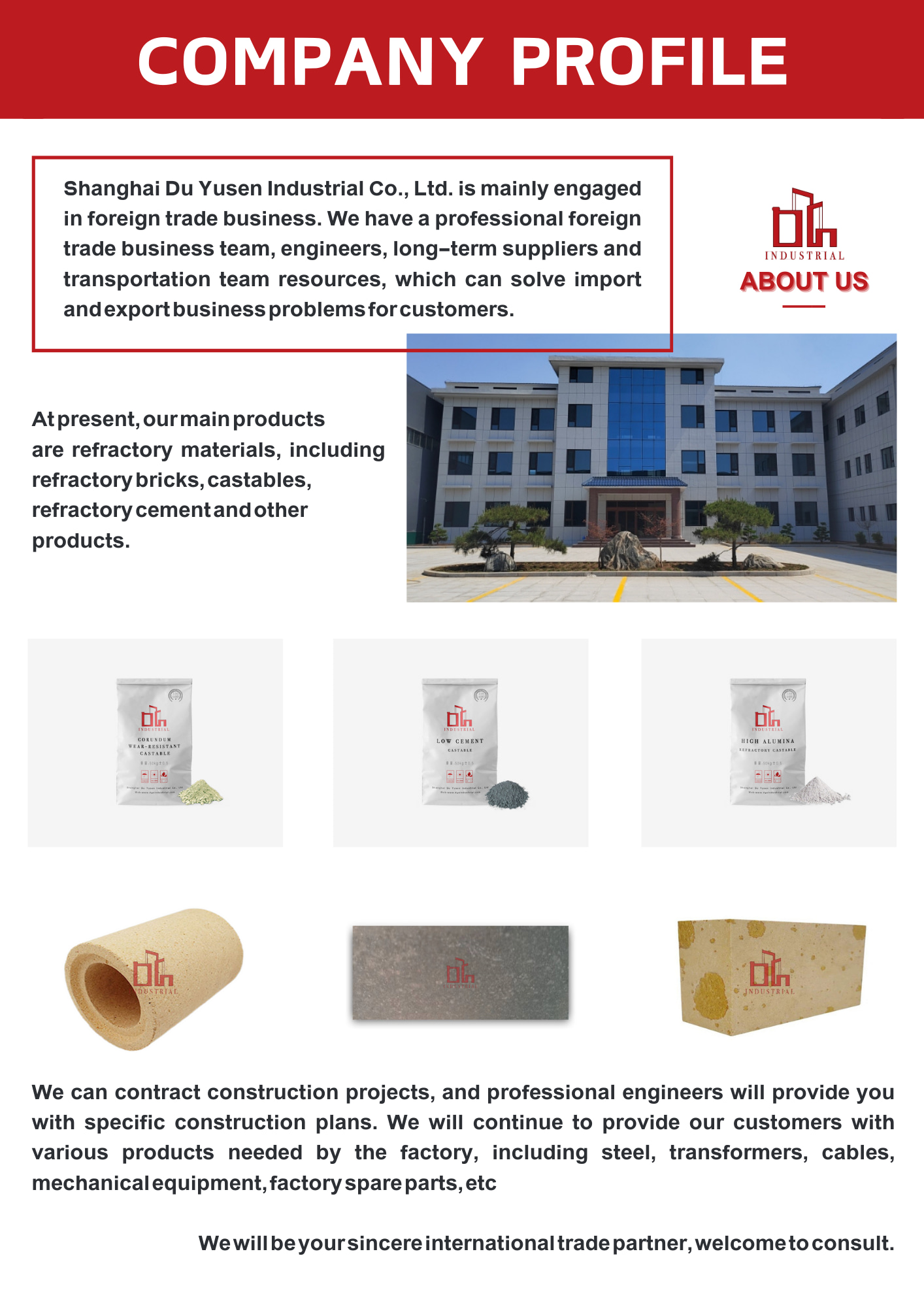

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

| Item | DYSAM-70 | DYSAM-80 | DYSAM-85 | DYSAM-95 | |

| ω(Al2O3+MgO)/% ≥ | 70 | 80 | 85 | 95 | |

| Bulk density(110℃×24h after drying)/(g/cm³) ≥ | 2.6 | 2.8 | 2.85 | 2.95 | |

| Normal temperature compressive strength, MPa | 110℃×24h after drying ≥ | 20 | |||

| 1000℃×3h after firing ≥ | 30 | ||||

| Test temperature×3h after firing ≥ | 50(1500℃) | 50(1550℃) | 60(1550℃) | 60(1600℃) | |

| Heating permanent line change, % | Test temperature×3h | -0.5~+1.5 | -0.5~+1.8 | -0.2~+1.8 | 0~+1.0 |

| (1500℃) | (1550℃) | (1550℃) | (1600℃) |

Product features:

1. Excellent fire resistance and fire resistance;

2. Inorganic materials, safe and environmentally friendly;

3. Extremely strong corrosion resistance and weather resistance;

4. High strength, strong adhesion and good anti-sag performance;

5. Good shock resistance, small shrinkage, and no hollowing or cracking;

6. Colorless and odorless, no toxic gas released at high temperature;

7. Excellent construction performance, construction can be done by adding water, simple and convenient.

Applications:

Aluminum-magnesium refractory castables are widely used in ladles for medium and small mold castings. The average ladle age is 60 to 80 times. The consumption of refractory materials per ton of steel is reduced by about 70% compared with clay ladle bricks.

Tags :